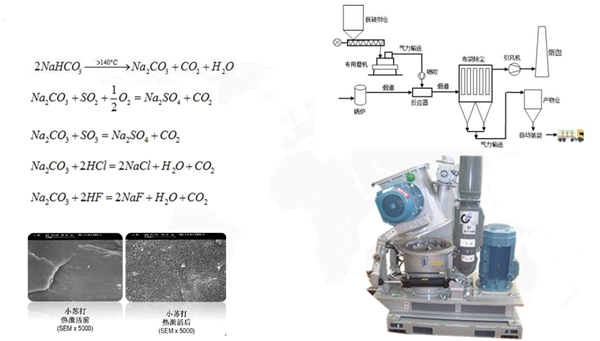

Working principle of Dry desulfurization technology - dry powder injection desulfurization (SDS) uses NaHCO3 as desulfurizer and is injected into the SDS reactor in the state of ultra-fine powder. The ultra-fine sodium bicarbonate powder is decomposed into highly active sodium carbonate and carbon dioxide under the action of high-temperature flue gas. The highly active Na2CO3 is fully contacted with SO2 and other acidic media in the flue gas to produce a chemical reaction, which is absorbed and purified. This method has the advantages of high desulfurization efficiency, simple system and simple control The ultra-fine grinding system of desulfurizer is the key point of this desulfurization method. This method is suitable for flue gas treatment with Low SO2 content.

Advantages of sodium bicarbonate powder process (SDS dry desulfurization) technology:

a. no temperature drop, and the flue gas temperature remains unchanged. The flue gas temperature after desulfurization is higher than that of other processes, and more heat can be recovered.

b. Small resistance and low power consumption.

c. The dust concentration at the inlet of the dust collector (the dust concentration in the flue gas after injecting sodium based dry powder) is less than 5g/nm3, which reduces the load of the dust collector, reduces the operating resistance of the dust collector, reduces the operating power consumption, and improves the service life of the dust collector.

d. Simple structure, flexible adjustment, good controllability and very small maintenance workload.

e. Dry treatment, no waste water, and the system does not need anti-corrosion treatment.

f. Small footprint.

EXAMPLE PROJECT

A. Project location: Henan, China