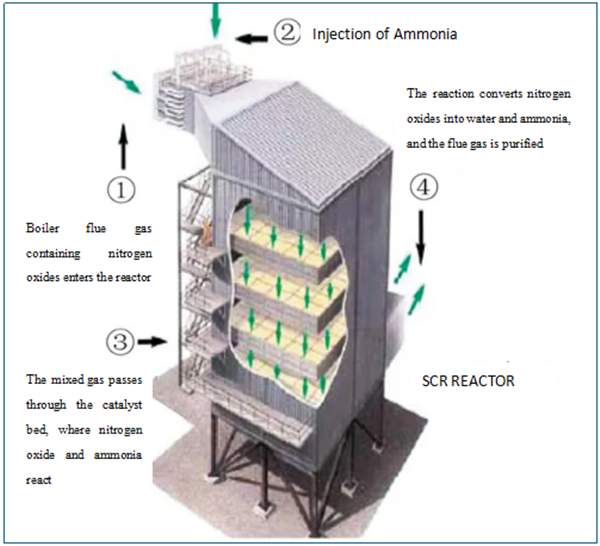

A. SCR

Working principle of SCR de-nitration device - the principle of selective catalytic reduction (SCR) de-nitration is to selectively reduce NOx in flue gas into non-toxic and pollution-free N2 and H2O with reductant under the action of a certain temperature and catalyst.

SCR de-nitration device has high purification rate, which can reach more than 85%; Compact process equipment and reliable operation; The reduced nitrogen is discharged without secondary pollution.

LANBEN can customize the de-nitration catalyst for our client according to the composition, characteristics, efficiency and customer requirements of the flue gas of the project, and select high activity catalyst with long service life, so as to reduce the operation cost and maintenance cost.

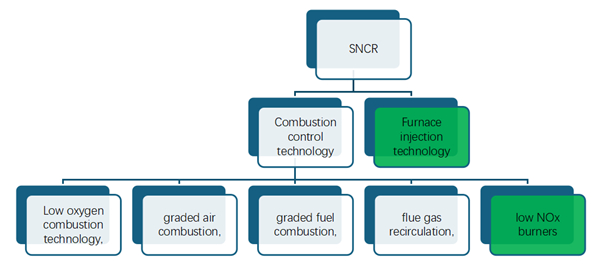

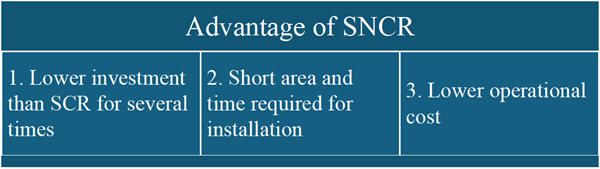

B.SNCR

The mature method of denitrification by injection in the furnace is ammonia injection method, which is a method of selectively reducing NOx emission. When no catalyst is used, the reaction of NH3 reduction of NOx can only be carried out in a narrow temperature range of 950 ~ 1050℃, so this method is also called selective non-catalytic denitrification method. The ammonia injection site is generally in the upper furnace flue gas temperature in the area of 950 ~ 1050℃. Two problems should be solved by this method: first, the selection of ammonia injection point should ensure that the ammonia injected can react with the flue gas in the range of 950 ~ 1050℃ when the boiler load changes; Second, the choice of the amount of ammonia spray should be appropriate. Using this method can generally reduce NOx by 30% ~ 70%.

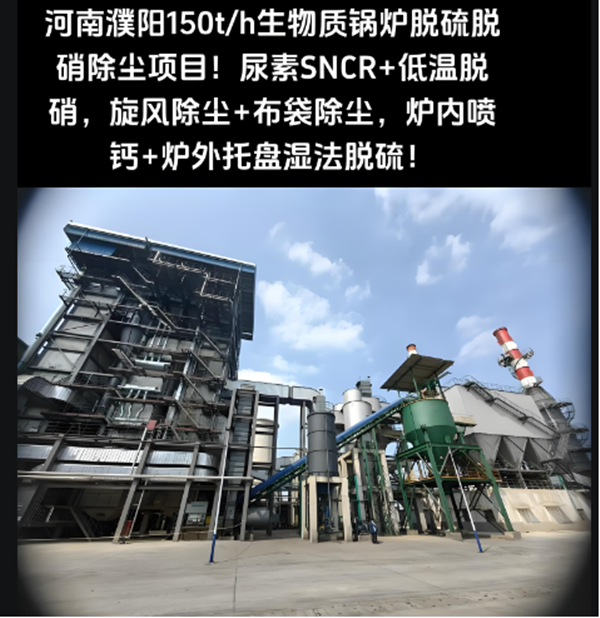

PROJECT EXAMPLE:

a. SCR (selective catalytic reduction)

Project location: 3X1000MW, Yuhuan, Zhejiang, China

b. SNCR

150TPH Biomass boiler with Urea SNCR + low temperature DeNOX+ Bag house +Wet FGD.