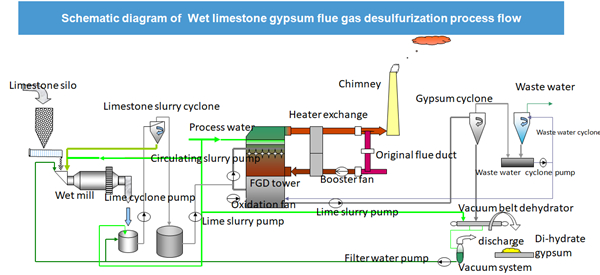

Working principle of the principle of limestone gypsum:

Wet flue gas desulfurization process is to use the slurry made of limestone powder as the desulfurization absorbent, contact and mix with the flue gas entering the absorption tower after cooling, and the sulfur dioxide in the flue gas reacts with the calcium carbonate in the slurry and the added oxidizing air to generate dihydrate gypsum. The desulfurized net flue gas will be discharged into the atmosphere through the chimney after water droplets are removed by the demister, heated by the flue gas heat exchanger and heated.

The main advantages of gypsum desulfurization gypsum method are: wide range of applicable coals, high desulfurization efficiency (when some devices have ca/s=1, the desulfurization efficiency is greater than 90%), high utilization rate of absorbent (can be greater than 90%), high equipment operation rate (up to more than 90%), high reliability of work (the most mature flue gas desulfurization process), rich and cheap sources of desulfurizer limestone. Gypsum desulfurization is the most commonly used method of wet desulfurization. It is one of the most popular and mature technologies for flue gas desulfurization of large units at present.

EXAMPLE PROJECT

A. Project location: 1X 1000MW, Shanxi, China