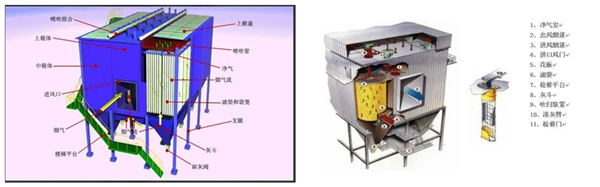

Working principle of bag house: The bag type dust collector is composed of an ash hopper, an upper box, a middle box, a lower box and other parts. The upper, middle and lower boxes are divided into chambers. During operation, the dusty gas enters the ash hopper from the air inlet, the coarse dust particles directly fall into the bottom of the ash hopper, the fine dust particles enter the middle and lower boxes with the turning of the air flow, and the dust accumulates on the outer surface of the filter bag. The filtered gas enters the upper box to the air purification chamber and is discharged to the atmosphere through the exhaust fan. The ash cleaning process is to cut off the air duct at the clean air outlet of the room first, so that the bag of the room is in a state of no air flow (the air is stopped and the ash is cleaned in each room). Then open the pulse valve and use compressed air for pulse blowing ash removal. The closing time of the shut-off valve is enough to ensure that the dust stripped from the filter bag after blowing settles to the ash hopper, avoiding the phenomenon that the dust is separated from the surface of the filter bag and then attached to the surface of the adjacent filter bag with the air flow, so that the ash removal of the filter bag is complete, and the exhaust valve and pulse valve are fully automatically controlled by the programmable controller.

The bag filter of LANBEN adopts advanced structural design concept, selects advanced filter cloth materials and reputed manufacturer of Solenoid valve with best quality, and combines mature processing technology to reduce the probability of bag breakage and wear.

Characteristics of bag filter:

Simulation design of air distribution

Good air flow guide

The bag material is properly selected, and the filter bag is well designed and manufactured.

Project Example:

A. Bag house for Metallurgical Plant, Hebai China

B. Bag house for Cement Plant, Zhejiang China