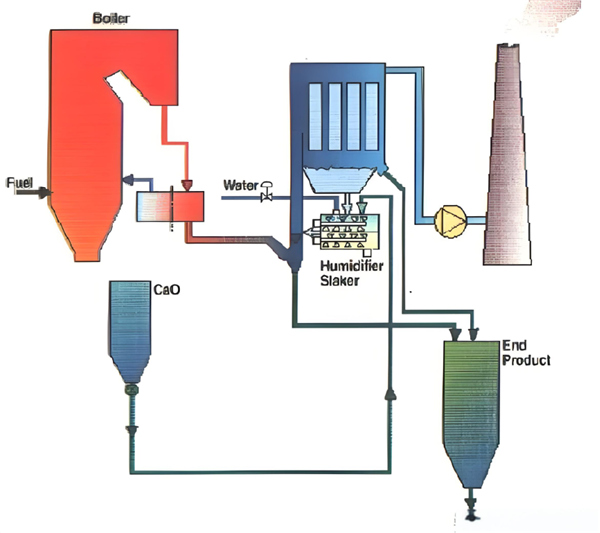

The raw flue gas from the boiler dust remover enters from the bottom of the absorption tower, and the hydrated lime is sent to the absorption tower through the conveying device. The fluidized material and the sulfur dioxide, hydrogen chloride and other acidic substances in the flue gas react chemically in the reactor to remove most of the sulfur dioxide, hydrogen chloride, etc; The flue gas is discharged through the top outlet of the absorption tower and then enters the bag dust collector to remove most of the dust. Most of the dust removed by the bag dust collector circulates through the air chute into the absorption tower for secondary reaction, and a small amount is discharged through the ash discharge device to the ash conveying system. The purified flue gas is discharged into the atmosphere through the chimney through the induced draft fan.

I.Typical process flow of CFB semi dry process

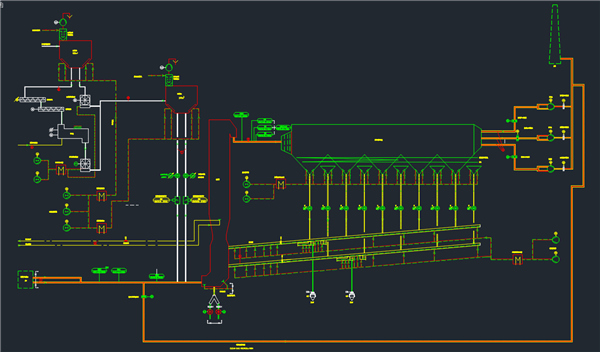

II.Schematic diagram of flue gas circulating fluidized bed

Semi dry desulfurization has the following advantages:

a. Simple process and low investment

b. Small floor area and low cost

c. Dry desulfurization by-product, no waste water, no corrosion

d. High desulfurization efficiency >90%

e. SO3 completely removed

f. No flue gas reheat system is required

g. Remove heavy metals without pollution

EXAMPLE PROJECT:

A. Project location: 1X150MW, Shandong, China